Nondestructive

rechargeable battery

inspection systems

The world’s first technology for nondestructive analysis of rechargeable battery failures

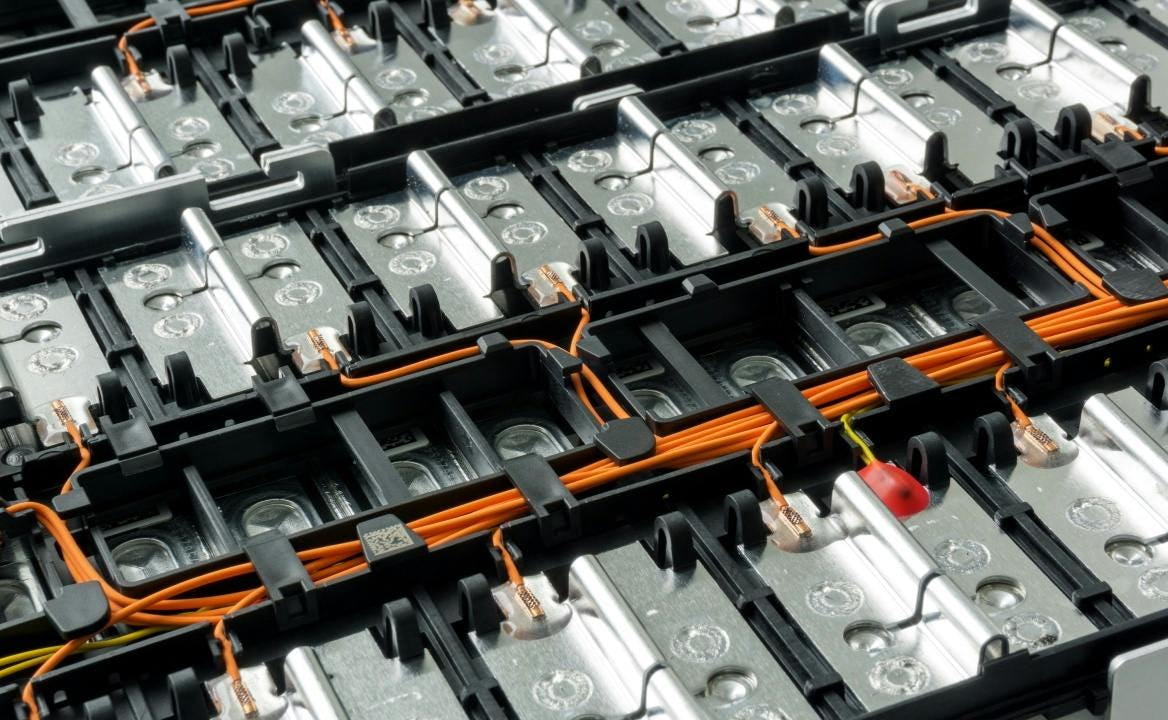

While the demand for lithium-ion storage batteries is on a rise because of their material properties, defects in such batteries can cause heat generation and ignition. The “Storage Battery Nondestructive Imaging Diagnostic System” developed by IGS can measure the electric current-density distribution inside storage batteries, thus enabling nondestructive failure analysis and quality control.

Direct Assessment of Electric Current-Density Distribution Inside Batteries

Our system can directly measure the electric current-density distribution within a battery, which is crucial for its operation and longevity. This capability allows us to accurately identify the root cause of any failures, enhancing both diagnostic precision and battery reliability.

Nondestructive Inspection of Battery Internal Current

Our technology allows for the assessment of the internal electric current status without damaging the battery, ensuring that it continues to operate with the same quality and performance as it had before testing.

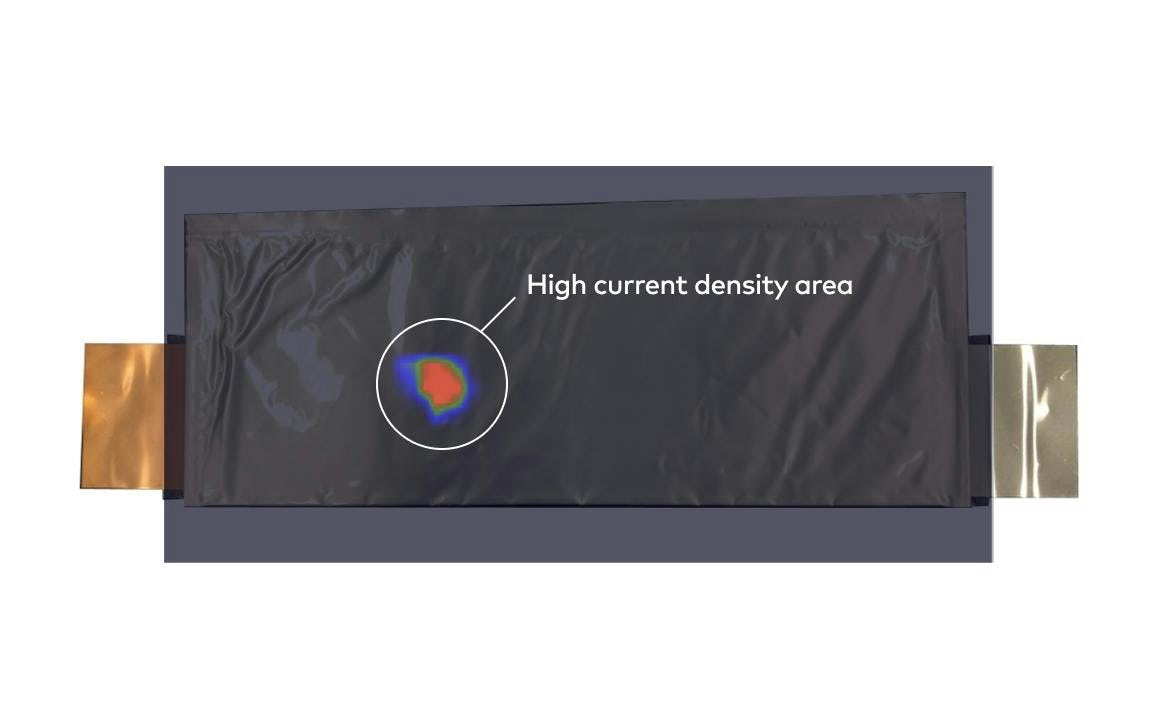

Detection of Minute Short Circuits in Shipped Batteries

Our technology can identify minor short circuits in batteries that have already been deemed functional. This capability allows us to detect slight spatial irregularities in electric current density, even before a short circuit occurs, ensuring optimal battery performance and reliability.

Challenges with Conventional Rechargeable Battery Testing

Traditional methods for inspecting rechargeable batteries have proven inadequate, leading to numerous ignition incidents

Pre-shipment inspections often rely on voltage drop tests (aging tests) after charging. Despite passing these tests, many batteries have still experienced explosions, highlighting a growing social concern in recent years.

Innovative Solutions

The IGS Approach

Using a proprietary calculation theory, IGS visualizes density distribution and short-circuit locations within storage batteries

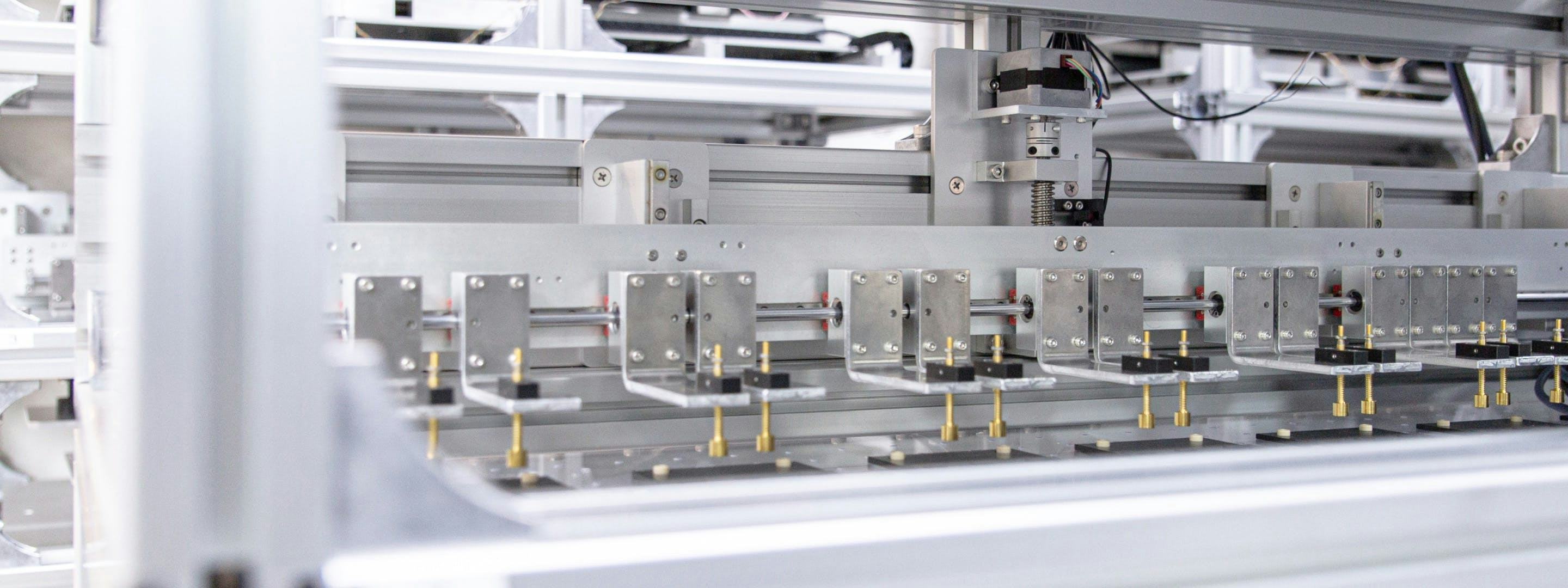

Our nondestructive imaging diagnostic system measures the magnetic field generated by electric current using an ultra-sensitive magnetic sensor, identifying potential failure points. Since the system applies only alternating current, evaluations are performed without damaging the battery.

The nondestructive storage battery imaging diagnostic system automatically measures the battery's magnetic field, calculating electric current using software based on inverse analysis theory

The data is visualized, highlighting areas with irregular electric concentration in different colors, enabling easy identification of potential faults.

Advantages of IGS Nondestructive Battery Testing

Our system visualizes the electric current path and density distribution within the battery, identifies potential design risks, and assesses safety for battery recycling.

Conventional testing

Self-discharge quantity

Impossible

Yes

IGS storage battery image diagnostic system

Current density spatial distribution

Possible

No

Self-discharge quantity

Current density spatial distribution

Impossible

Possible

Yes

No

Related Articles

“Local electric current reconstruction theory for non-destructive inspection inside battery cell using magnetic field measurement”

Kenjiro Kimura, Yuki Mima

Subsurface Imaging Science & Technology. 1 [16](2017)1, October 2017